Build a Foundation with Strength and Win Coexistence with Integrity

About FRJ Industries

"Pioneer in Precision Intelligent Manufacturing, Specialist in the Sheet Metal Sector."

We focus on every detail across all aspects of sheet metal processing and manufacturing.

By virtue of exquisite craftsmanship and cutting-edge technology, we craft high-quality, high-performance products for global customers.We exercise strict oversight over every stage from design to production, ensuring all products comply with the highest quality standards.

Through continuous innovation and optimization of manufacturing processes, we strive to elevate the sheet metal manufacturing industry to new heights and become a globally trusted supplier for customers worldwide.

Specialist in the Sheet Metal Sector

Thank you for your interest in FRJ Industries! Regarding the matters you inquired about (e.g., quotation, cooperation, product craftsmanship), we can provide tailored, accurate solutions based on your specific requirements—including your industry, product specifications, material needs, order volume, and more.

Please reach out to us at willyann@foxmail.com. We will respond with a professional reply within 24 hours.

We look forward to the possibility of collaborating with you!

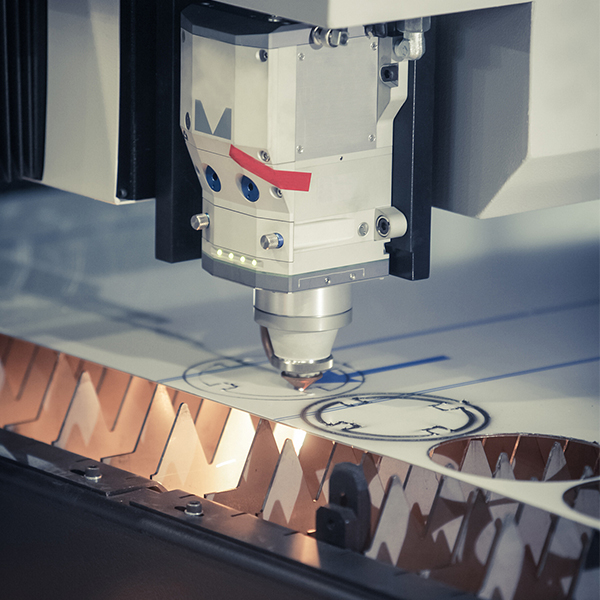

Laser Cutting

Application Scenarios: Application Scenarios: Suitable for manufacturing precision parts, chassis shell hole drilling, decorative panels, electrical brackets, structural components with complex contours, etc.

Laser Cutting of Metal

We support customization based on your specific requirements, and will recommend the optimal solution according to actual application scenarios. Non-standard customization services are available to meet your specialized needs.

Features

a. High cutting precision (up to ±0.1mm) with smooth, burr-free cuts

b. High processing efficiency, compatible with various metal materials

c. Flexible adaptation to complex contour processing requirements

Delivery Guarantee

Standard equipment is in stock for quick delivery. The lead time for customized equipment is 30–60 days. We will arrange production processes rationally to ensure on-time delivery.

Welding

Application Scenarios: Frame structures (e.g., rectangular skeletons welded from cold-rolled steel plates), panel-side plate connections, industrial electronic chassis (e.g., outdoor communication chassis), and irregular structures (e.g., protruding interface mounting seats, internal reinforcing ribs)

Gas shielded metal welding

We offer a one-year warranty. We provide free replacement parts to ensure the rights and interests of customers during the warranty period.

Installation & Commissioning

We provide professional on-site installation and commissioning services for customers to ensure the normal operation of the equipment.

Data Support

Provide downloadable text materials and instructional video operations to facilitate customers' access and learning at any time.

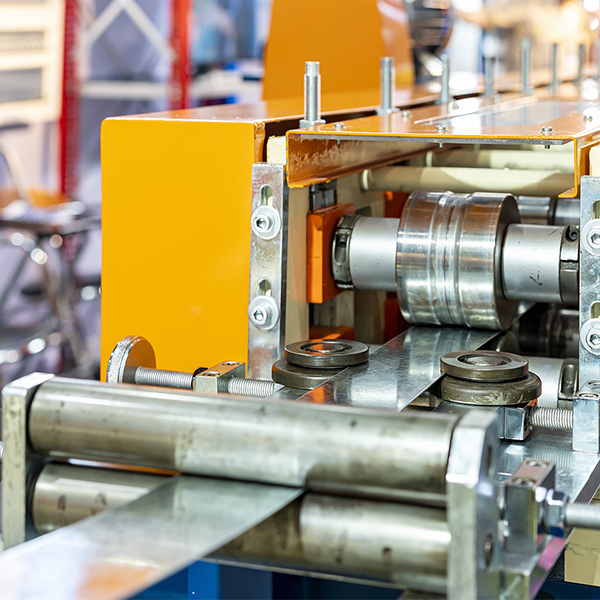

Roller Forming

Application Scenarios: Pipes/profiles (automotive exhaust pipes, PVC water pipes), threaded parts (bolts), precision shafts, etc.; seals (O-rings); concrete drainage pipes; precision conduits, wheel hubs, etc.

Applicable Metals

Suitable for metal materials (e.g., cold-rolled steel, aluminum, copper). Roller forming parameters can be flexibly adjusted based on material properties to ensure forming precision and structural stability.

Process Features

Adopts continuous roller forming process with high production efficiency; forming tolerance is controllable within ±0.1mm for stable precision; high material utilization rate, suitable for mass production of various profiles/pipes.

Price Description

Provide transparent quotations based on forming specifications, material types and order quantities, balancing cost and production efficiency to offer cost-effective roller forming solutions for customers.

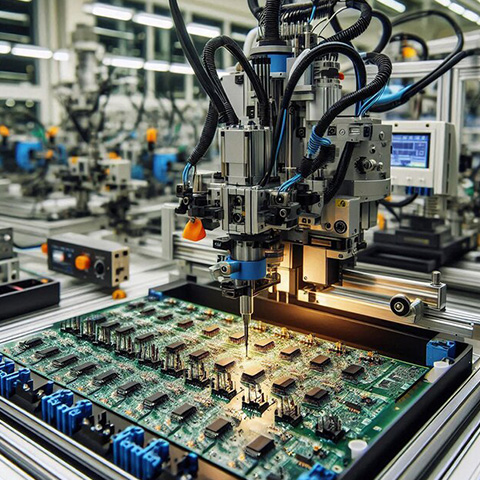

Milling

Application Scenarios: Guide rail mounting surfaces on chassis panels, motherboard fixing planes, slotted holes (for heat dissipation) milled on chassis side panels/panels, stepped holes (for adapting to different-spec interfaces), T-slots (for easy sliding adjustment of internal components).

Applicable Milling Processes

Applicable Milling Processes: Compatible with CNC milling, supporting face milling, profile milling, hole system milling, etc. Processing paths can be customized based on workpiece structure requirements.

Warranty Service

We offer a 1-year warranty. For non-human quality issues of milled parts during the warranty period, we provide free repair or replacement services.

Installation & Commissioning

We provide professional on-site installation & commissioning for equipment with milled structures, ensuring the adaptability and normal operation of milled components and the whole machine.

Data Support

We provide technical documents and operation guide videos for milling processing, enabling customers to access milled component specifications and maintenance points.

General Materials

Surface Treatment

Enhance quality: Offer a variety of surface treatment processes to improve the corrosion resistance, wear resistance, aesthetic appeal and functionality of products.

Processing Case

- Phone

- *Title

- *Content

We will give you a professional response within 24 hours.