A global premium sheet metal product manufacturer

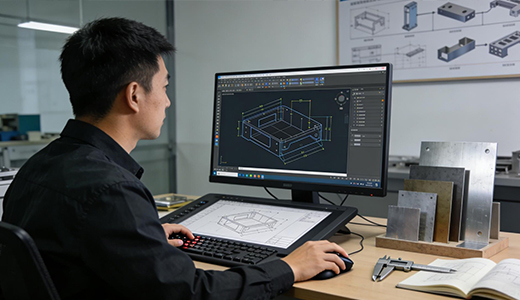

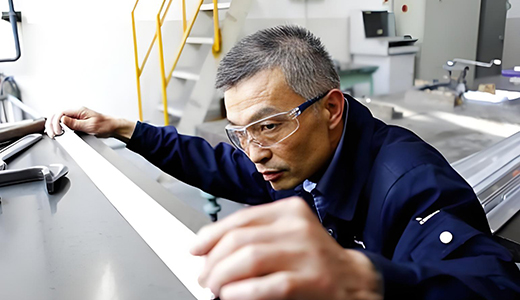

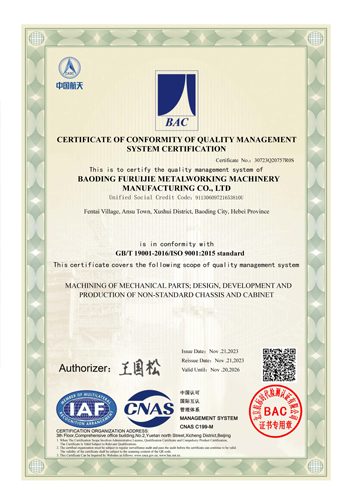

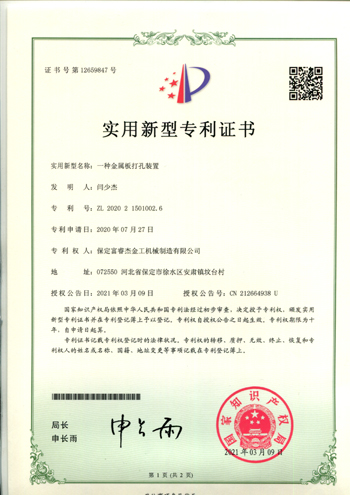

Ingenious craftsmanship forges reliable products; quality service adapts to diverse scenarios

- Small batch MOQ (MOQ × 1 ) + 15-day bulk delivery

- 7-day sampling + 24-hour technical docking

- Process precision/protection level matches industry scenarios